4000 + m²

Factory area

Factory area

Can be produced daily

Are produced annually

Cooperating countries

We have a professional R&D team dedicated to developing new products and improving existing products. Our R&D capabilities enable us to respond quickly to market demands and provide customized solutions for our customers.

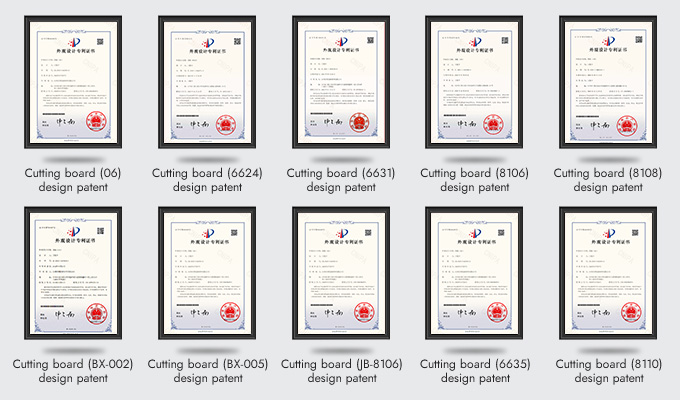

One national invention patent

8 utility patents

More than 20 product design patents

Injection molding machines work simultaneously, with a daily output of 50,000 cutting boards

Fully automatic mechanized production, with a daily output of 50,000 cutting boards

3 fully automatic packaging production lines work simultaneously, with a daily output of 100,000 cutting boards

Customized LOGO, with a daily output of 50,000 cutting boards

Choose a reputable polypropylene supplier and regularly review its qualifications and quality management system to ensure that the source of raw materials is reliable.

Each batch of polypropylene raw materials must be strictly tested before entering the factory, including molecular weight distribution, melt flow rate (MFR), density, color and impurity content, to ensure that it meets the physical and chemical properties required for the production of cutting boards.

More Quality Control

According to the characteristics of polypropylene, set appropriate process parameters such as heating temperature, mold temperature, injection speed and cooling time to ensure sufficient melting and uniform distribution of materials, reduce internal stress, and improve the structural integrity and dimensional stability of the cutting board

Real-time monitoring of various parameters during the production process, such as mold temperature, material temperature and pressure, to ensure stable process conditions and timely adjustments to deal with abnormal situations

More

Check whether the surface appearance of the cutting board meets the standards, use precision measuring tools to verify that the cutting board meets the design requirements, and conduct performance impact resistance tests to meet the standards.

Test the chemical stability of the cutting board to ensure that no harmful substances migrate into the food, add antibacterial agents (such as zinc ions and silver ions) to verify its antibacterial effect, and effectively inhibit bacterial growth under long-term use

More

Use moisture-proof and dust-proof packaging materials to protect the cutting board from external contamination and extend the shelf life

Establish reasonable storage conditions to avoid the impact of high temperature and humid environment on the performance of polypropylene cutting boards

MoreWe are committed to environmental protection and sustainable production practices. We use environmentally friendly materials and strive to minimize waste and energy consumption in the production process